Add to Cart

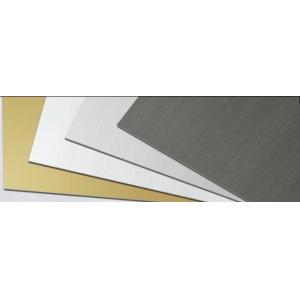

Good quality Zinc composite panel 980*2500*4mm (0.70/0.70mm) for wall decoration

Dimension: 980*2500*4mm (0.70/0.70mm)

The Zinc composite panel combines Zinc plate characteristics (metallic feeling, self-healing, long life, good flexible) with the advantage of high strength, smooth and good, light weight, low price of composite panel. It can be used in the high-grade building walls, roof and interior decoration

Physical/Mechanical Property

| Item | Item Description | Standard | Condition | Results |

| 1 | Density | ASTM D792-02 | Absolute alcohol,23ºC | 2.147g/cm3 |

| 2 | Water resistance | ASTM D870-02 | 99ºC, 2H | No visual Changes |

| 3 | Thermal Expansion | ASTM D696 | - | 193.0μm/m·ºC |

| 4 | Heat deflection Temperature | ASTM D648-07 | Heating rate:120ºC/h Load:1.82Mpa | 94.8 ºC |

| 5 | Shear Resistance | ASTM D732-02 | Speed:1.3mm/min | 30.5Mpa |

| 6 | Shear Strength | 10528N | ||

| 7 | Tensile Strength | ASTM D638-03 | Speed:500mm/min | 43.8MPa |

| 8 | Flexural Strength | ASTM D790-07 method A | Speed:1.9mm/min Span:70mm | 99.5MPa |

| 9 | Flexural Module | 9390MPa | ||

| 10 | 180oC Peel strength | ASTM D903-98 | Seperation Rate: 152.4mm/min | 64kg/mm |

Long service life manifested in :

There is no need for Zinc Surface to make any painting and any other corrosion treatment, because it has a natural layer of dense oxide (Zinc carbonate ), and prevent further erosion.

With self-healing function, the Zinc panel can automatically heal without leaving traces after some time.

Zinc composite panel is a kind of new high grade construction, takes titanium zinc plate as its face plate, and aluminum as rear plate, high-pressure low density polythene (LDPE) as core materials.

Even under the poor atmosphere condition, the service life for 1mm thick Zinc will be more than 200 years.

| Top ZINC Thickness(mm) | Rear Aluminium Thickness(mm) | Total Thickness (mm) | Intensity Equal to Solid ZINC Thickness(mm) |

| 0.5 | 0.5 | 4.0 | 2.5 |

| 0.7 | 0.7 | 4.0 | 3.0 |

| Testing Items | Unit | Performance Indicator |

| Flexural Strength | Mpa | ≥60 |

| Flexural Modulus | 104 Mpa | ≥2.0 |

| Penetrating Resistance | KN | ≥7.0 |

| Shear Strength | Mpa | ≥22.0 |

| 180°Peel off Strength | N/mm | ≥7.0 |

| Thermal Expansion | ℃ | ≤ 4.00×10-5 |

| Thermal Deformation Temperature | ℃ | ≥95 |

| Boiling water Resistance | No effect | |

| Fire Resistance | GB8624 Class B | |